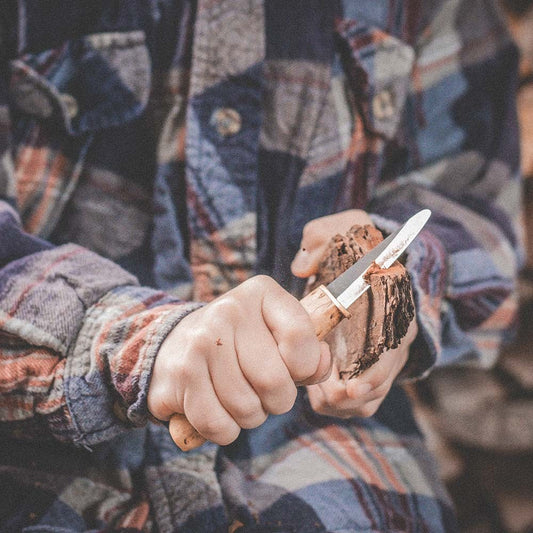

Why the process behind the blade truly matters

At first glance, two knife blades can look identical. Same shape. Same steel. Same sharpness.

But how a blade is made determines how it will perform, not just on day one, but after months and years of real use.

This article explains the difference between a blade whose shape is created by cutting or stamping, and a blade that is then further drop-hammer forged. The difference is not always immediately visible, but it becomes clear over time.